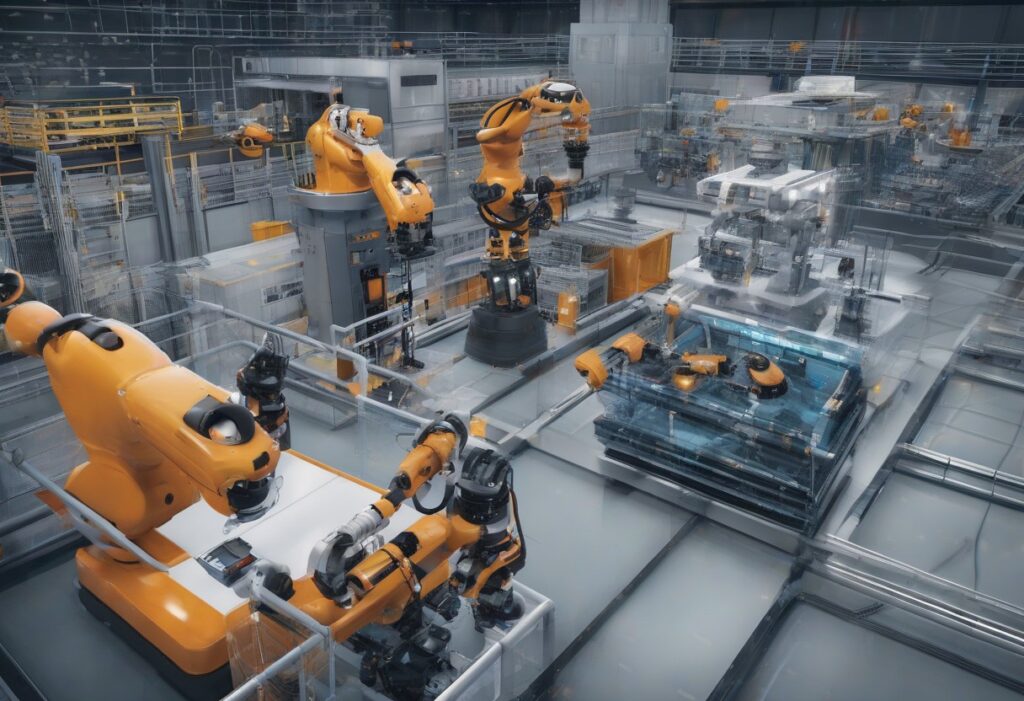

In the world of industrial automation, AI tools that use ControlNet are becoming game-changers. These tools are helping businesses streamline processes, reduce downtime, and enhance communication between machines. ControlNet, a robust industrial network protocol, provides the backbone for reliable, real-time data transmission, making it a perfect fit for AI integration. By combining AI with ControlNet, industries can achieve improved automation, predictive maintenance, and optimized performance.

AI tools that use ControlNet enable real-time decision-making by analyzing data from various devices connected through the network. These tools can monitor equipment health, identify patterns, and predict failures before they happen. This proactive approach helps companies avoid costly repairs and downtime, ensuring smoother operations. The combination of AI and ControlNet allows for smarter factories where every machine and device is connected, creating a seamless flow of information. In this blog, we will explore the top benefits and examples of how AI tools are enhancing ControlNet networks, making industrial automation smarter and more efficient.

How AI Tools That Use ControlNet are Revolutionizing Industrial Automation

AI tools that use ControlNet are significantly transforming industrial automation by providing advanced capabilities in data analysis, decision-making, and network communication. ControlNet, known for its reliability and high-speed data transfer, serves as the ideal foundation for integrating AI tools into industrial systems. These AI tools can monitor machinery in real time, identifying potential issues and optimizing processes. By combining AI with ControlNet, businesses can achieve more efficient automation, where machines learn from data to improve operations. This results in reduced downtime, lower maintenance costs, and enhanced productivity. AI-driven ControlNet systems are becoming essential in sectors like manufacturing, energy, and transportation, where automation is key to success.

The Role of AI in Enhancing ControlNet: Key Benefits for Businesses

AI tools integrated with ControlNet offer businesses numerous advantages, especially in industries that rely on automation. With AI, ControlNet systems can go beyond simple data transfer and begin to analyze vast amounts of information in real time. This allows for smarter decision-making, reducing human error and improving efficiency. One of the key benefits is predictive maintenance, where AI tools can detect early signs of wear and tear in equipment, allowing businesses to address issues before they cause costly breakdowns. Additionally, AI-driven systems can optimize workflows, ensuring that machines and devices communicate seamlessly, leading to higher production rates. Businesses that leverage AI tools with ControlNet can enhance their competitive edge by improving both operational efficiency and cost-effectiveness.

Top AI Tools That Use ControlNet for Smarter Manufacturing

The use of AI tools with ControlNet is transforming the manufacturing industry by enhancing automation and efficiency. Several AI tools are designed specifically to work with ControlNet, allowing manufacturers to monitor and control their processes with precision. These tools provide real-time insights into equipment performance, production output, and system health. For example, predictive analytics tools can forecast when a machine is likely to fail, while machine learning algorithms help optimize production schedules based on real-time data. Additionally, AI tools can improve inventory management and quality control, leading to better resource allocation and fewer defects. By integrating AI with ControlNet, manufacturers can ensure more intelligent, responsive, and efficient manufacturing processes.

Why AI Tools That Use ControlNet are Essential for Predictive Maintenance

Predictive maintenance is one of the most significant benefits of AI tools that use ControlNet, especially in industries with high-value machinery. AI-powered systems can analyze the health of equipment connected through ControlNet, detecting patterns that suggest wear or potential failure. These systems monitor vibrations, temperatures, and other operational parameters to identify any deviations from normal functioning. With this early warning system, companies can schedule repairs before failures occur, significantly reducing costly downtime. The integration of AI with ControlNet allows businesses to transition from traditional, reactive maintenance practices to a more proactive, data-driven approach, which ultimately leads to longer equipment lifespans and lower maintenance costs.

Exploring the Future of AI Tools That Use ControlNet in Industrial Networks

The future of AI tools that use ControlNet is incredibly promising, with potential advancements that could further revolutionize industrial automation. As AI technology continues to evolve, the integration with ControlNet will likely become even more sophisticated. One exciting possibility is the use of deep learning algorithms, which can provide even more accurate predictive maintenance and process optimization. In the future, AI tools may not only monitor equipment but also automatically adjust system parameters to improve performance in real time. The continued development of AI and ControlNet could lead to fully autonomous manufacturing environments, where machines can self-optimize without human intervention. This would result in factories that are more efficient, adaptive, and capable of meeting the growing demands of the modern world.

Integrating AI with ControlNet: A New Era of Automation and Efficiency

Integrating AI with ControlNet is paving the way for a new era of automation and efficiency in industrial environments. Traditionally, automation systems have relied on predefined instructions and minimal real-time adjustments. However, by incorporating AI tools, ControlNet networks can evolve into self-learning systems that continuously adapt to changing conditions. This means that factories, energy plants, and other industrial settings can operate with a much higher level of efficiency and precision. AI tools help optimize energy usage, reduce waste, and improve the overall flow of materials through the production line. By combining the strengths of ControlNet’s reliable communication with the intelligence of AI, industries are stepping into a future where automation is not just reactive but proactive and self-improving.

How AI Tools That Use ControlNet Help Improve Factory Operations

AI tools that use ControlNet play a crucial role in improving factory operations by providing real-time insights and automation capabilities. These tools allow factories to optimize their operations in ways that were not possible before. AI-driven analytics can monitor production lines, detect bottlenecks, and suggest improvements, all in real time. Furthermore, AI can adjust operations dynamically to meet production goals, ensuring that factories run at peak efficiency. With AI tools working in conjunction with ControlNet, factories can achieve better resource management, lower costs, and increase overall output. The integration of AI into ControlNet networks helps ensure that factory operations are smooth, predictable, and optimized for success.

Unlocking the Power of AI and ControlNet for Seamless Communication

AI and ControlNet together unlock the power of seamless communication in industrial environments. By combining the robust, deterministic communication of ControlNet with the advanced processing capabilities of AI, industries can achieve highly reliable and intelligent networks. AI tools can analyze data from multiple machines, sensors, and devices connected via ControlNet, ensuring that information flows smoothly and in real time. This seamless communication enables faster decision-making, enhanced collaboration between machines, and improved coordination across entire production systems. With AI tools optimizing the data transfer and analysis on ControlNet networks, companies can ensure that their automation systems work more harmoniously, resulting in greater efficiency and productivity.

AI Tools That Use ControlNet: Redefining Real-Time Data Analytics

AI tools that use ControlNet are redefining how industries approach real-time data analytics. Traditionally, data analysis in industrial settings has been slow and reactive, but with AI tools integrated into ControlNet networks, data analysis is now faster and more accurate. AI can process vast amounts of data from sensors and equipment connected via ControlNet, providing immediate feedback and insights. This enables companies to make informed decisions quickly, whether it’s about optimizing production, adjusting workflows, or maintaining equipment. By leveraging the power of AI in real-time data analytics, industries can stay ahead of problems, make better decisions, and improve overall performance.

The Advantages of Using AI Tools That Leverage ControlNet for Process Optimization

Using AI tools that leverage ControlNet for process optimization offers numerous advantages, particularly for industries that rely on complex manufacturing processes. ControlNet’s real-time, deterministic communication capabilities provide the ideal platform for AI tools to optimize every aspect of production. These AI tools can identify inefficiencies in workflows, reduce energy consumption, and ensure that every step of the production process is as efficient as possible. Additionally, AI can make dynamic adjustments to improve processes on the fly, leading to continuous optimization. By integrating AI tools with ControlNet, industries can achieve not only cost savings but also higher product quality and greater consistency in their operations.

Conclusion

AI tools that use ControlNet are making a big difference in the world of industrial automation. By combining the power of artificial intelligence with ControlNet’s reliable network, businesses can improve their operations and make smarter decisions. These tools help machines talk to each other more effectively, predict problems before they happen, and keep everything running smoothly. This combination is changing how industries work, making them faster, smarter, and more efficient.

As technology continues to grow, we can expect even more improvements in AI tools that use ControlNet. The future looks bright, with machines getting smarter and factories becoming more automated. These changes will make businesses more competitive and help them save money. AI and ControlNet together are clearly shaping the future of industrial automation in a big way!

FAQs

Q: What is ControlNet?

A: ControlNet is an industrial network protocol that helps machines and devices communicate with each other reliably and quickly in factories and automation systems.

Q: How do AI tools help with ControlNet?

A: AI tools use the data from ControlNet to make better decisions, predict maintenance needs, and optimize factory operations in real time.

Q: Why is predictive maintenance important?

A: Predictive maintenance helps prevent expensive repairs by predicting when machines will break, allowing for timely fixes and reducing downtime.

Q: Can AI tools improve factory efficiency?

A: Yes! AI tools help improve efficiency by monitoring machines and workflows, fixing problems before they slow things down, and making processes smarter.

Q: Are AI tools that use ControlNet expensive?

A: While there may be an upfront cost, using AI tools with ControlNet can save money in the long run by reducing downtime, improving productivity, and lowering maintenance costs.